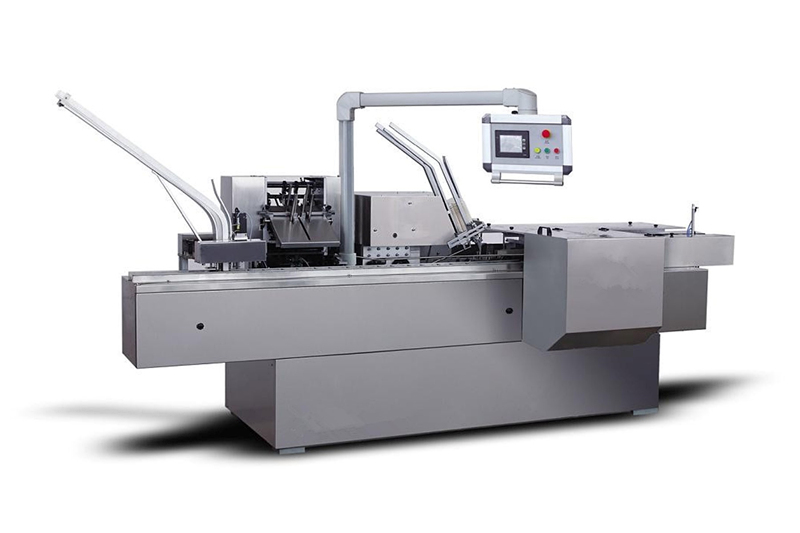

Shisha Tobacco Boxing Machine

Our shisha tobacco boxing machine is a high-tech integration of light, electricity and gas, which is suitable for automatic cartoning of a variety of products. The working processes includes the transfer of raw products, the auto open and transportation of boxes, the loading of raw material into the carton boxes, and sealing & closure of two ends of carton boxes.

The machine is made of high-quality stainless steel cover which is strictly in accordance with the “GMP” standard of the pharmaceutical industry. When it comes to the transmission system, it is designed with overload protection function with an emergency stop setting. The control system adopts a human-machine interface screen to ensure the personal safety of the operator.

Main Features:

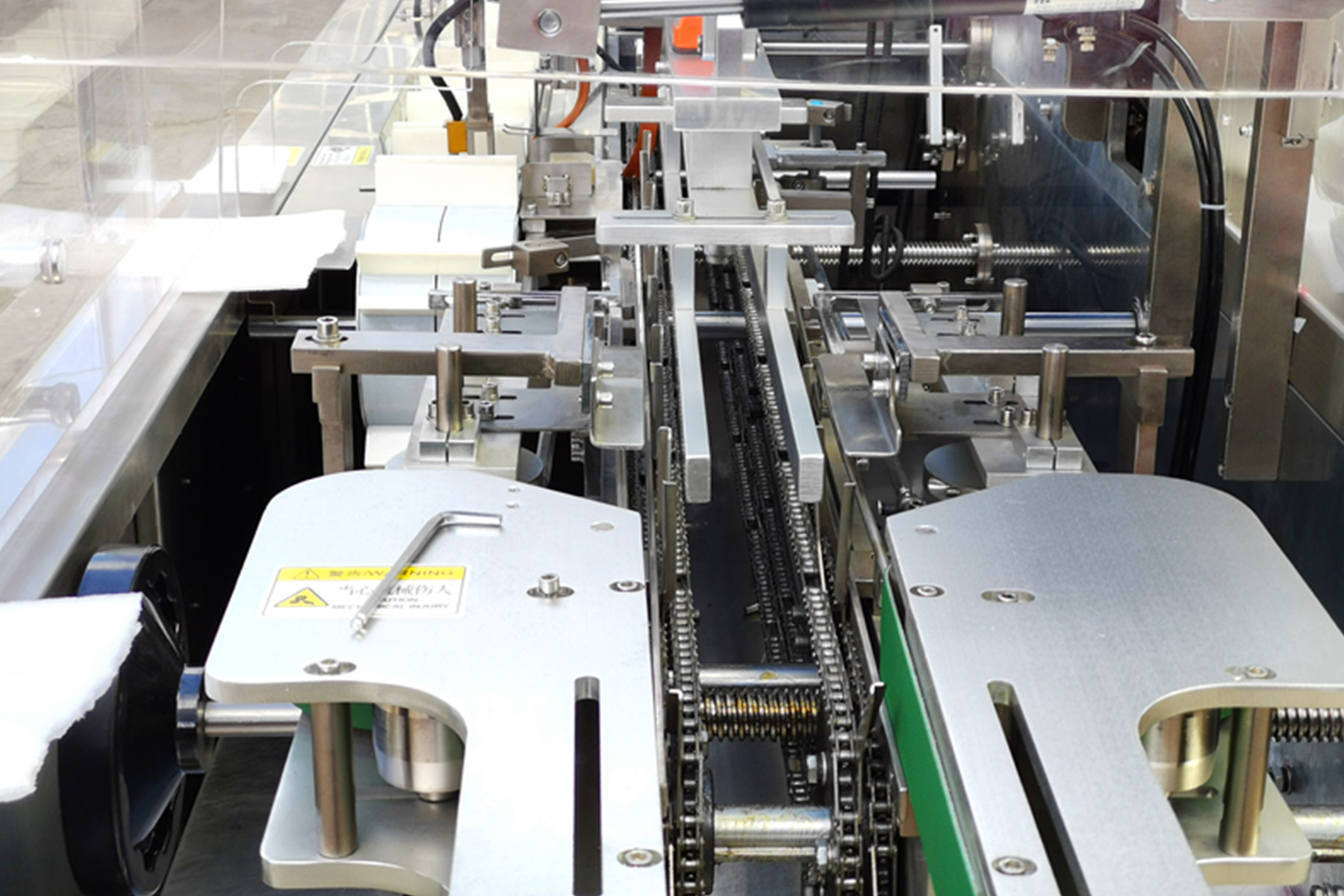

1. Adopt automatic feeding, open box, box, box and output. The packaging form, etc., the structure is compact and reasonable, and the operation adjustment is simple;

2, using servo / stepper motor and touch screen, PLC programmable control system, man-machine interface display operation is more clear and simple, high degree of automation, more humane;

3, using photoelectric eye automatic detection and tracking system, no product does not suck the box, to maximize the saving of packaging materials;

4, the packaging range is large, the adjustment is convenient, and the rapid conversion can be realized between various specifications and sizes;

5, the specification does not need to change the mold, just adjust to achieve;

6. When no product or product supply is not in place, the machine will not push the product when it is idling. When the product resumes supply, it will automatically run. The product enters the box and stops automatically and the main drive motor overload protection device is safer and more reliable.

7, automatic display boxing speed and counting:

8, according to customer requirements, the use of upturned safety shield, easy to operate, beautiful appearance.

9, can be linked with aluminum-plastic packaging machine, pillow packaging machine, three-dimensional packaging machine, bottling line, filling machine, labeling machine, inkjet printer, online weighing instrument, other production lines and other equipment;

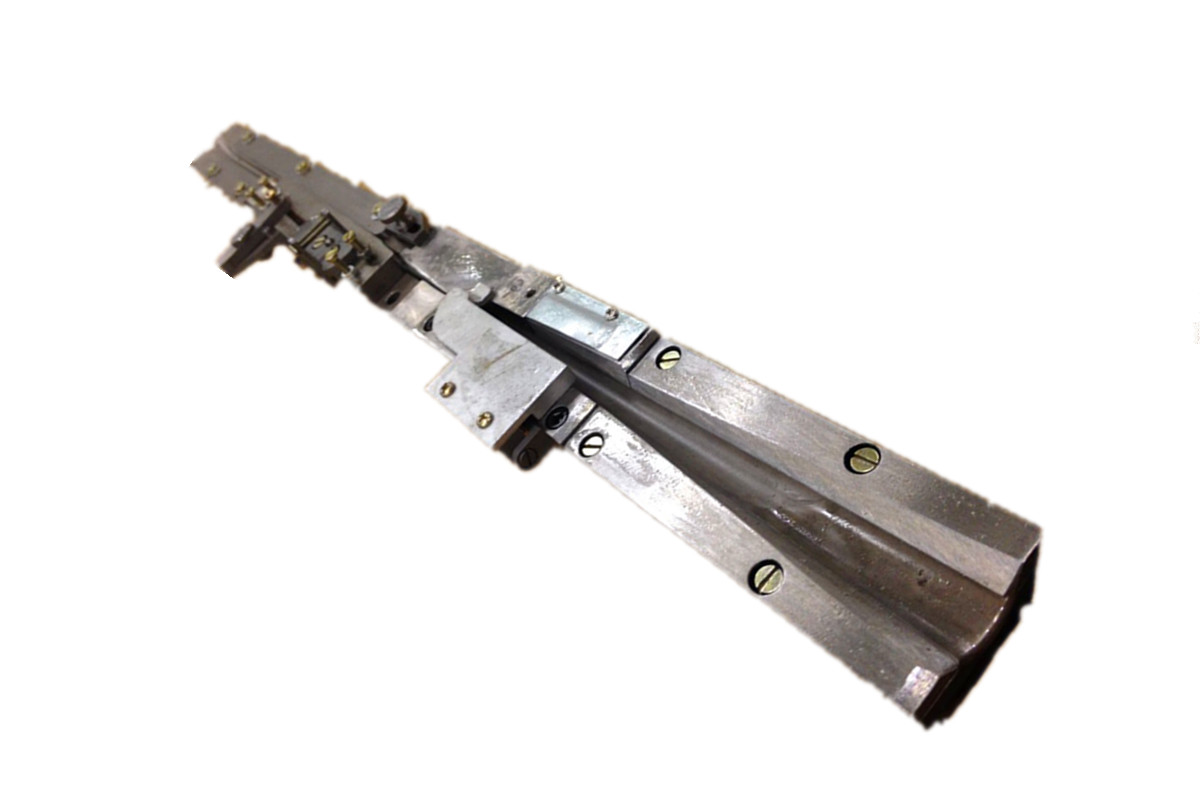

10. Various automatic feeders and box-entry systems can be designed according to the requirements of the packaging;

11. According to the customer’s requirements, the hot melt glue machine can be equipped with hot melt glue spray sealing box.

Machine Technical Specifications

| Type Of Raw Materials |

As Per Requirements |

| Machine Capacity |

60-100 boxes/min |

| Thickness Of Paper |

250—400g/m2 |

| Size Range |

L(60-250) x W(25X150) x H(15-70) |

| Air Compressor (Pressure) |

≥0.6MPa |

| Air Compressor (Consumption) |

20m3/h |

| Power Requirements |

220V—380V 50Hz 4kw |

| Machine Size |

2850*1500*1800mm |

| Net Weight |

1050 kgs |