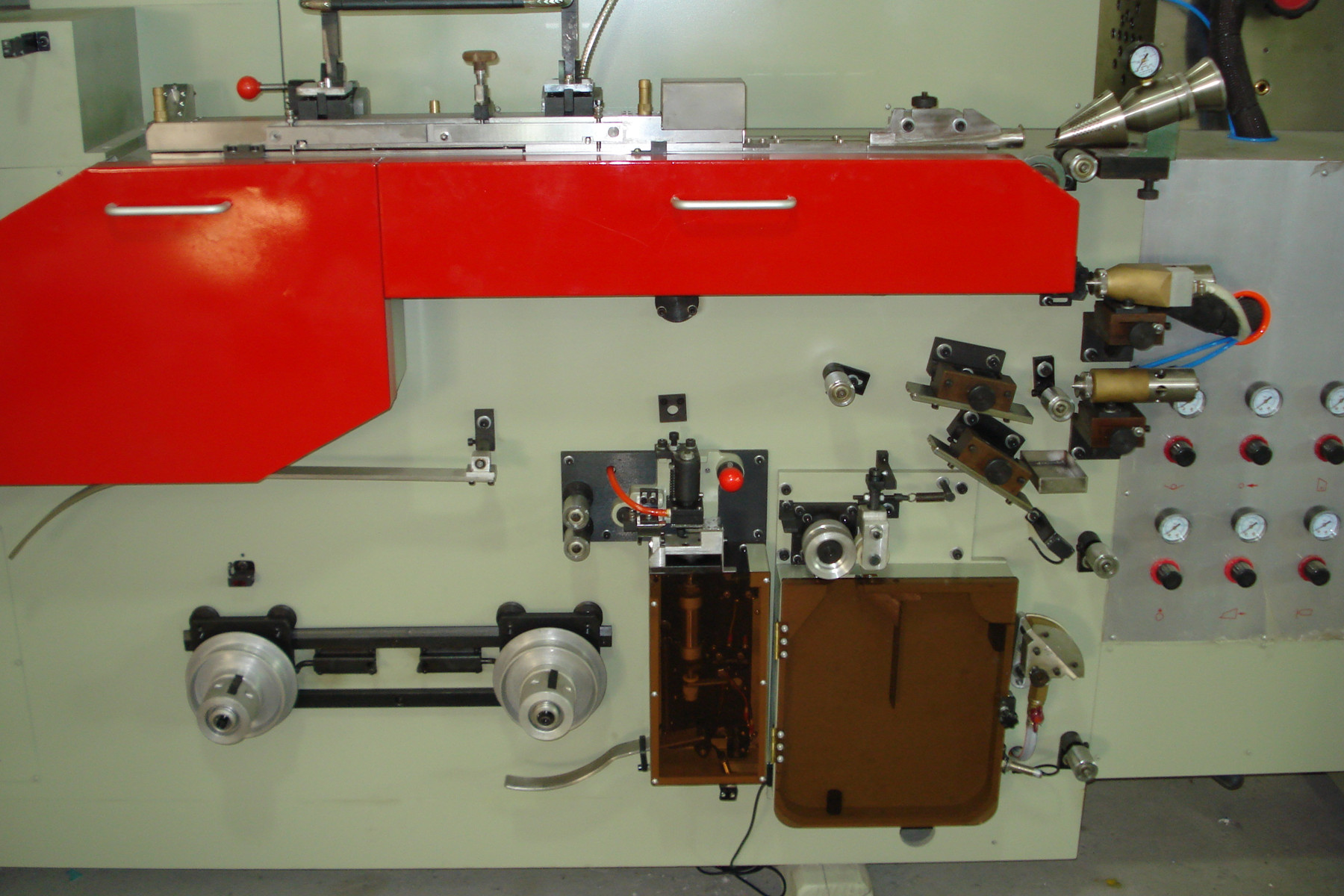

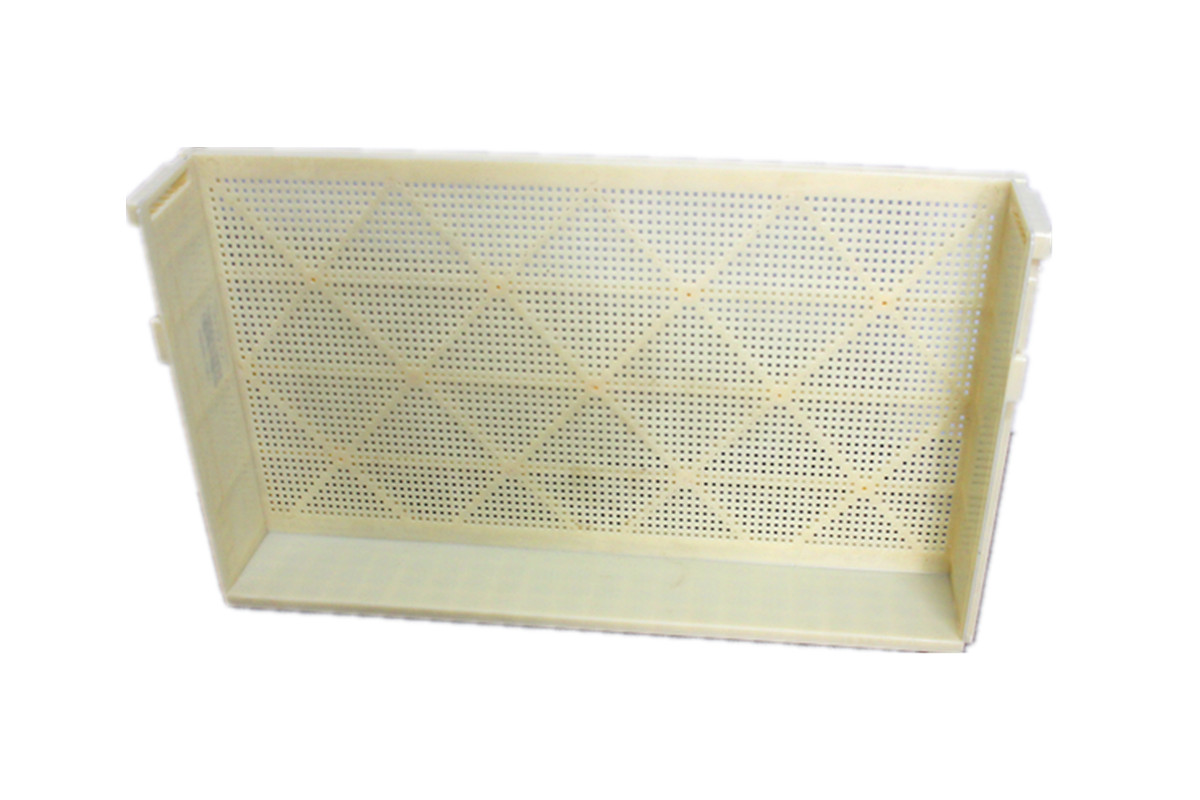

ZL23 Filter Rod Making Machine

ZL23 set of fiber filter rod forming machine consists of YL13 loose gluing machine andYL23 filter rod forming machine. It takes cellulose acetate tows or polypropylene tows as raw material, after air losing, thread losing, gluing, involution, side seal, forming and cutting, formed long filter tipping rod which meets the high-speed adapter request.

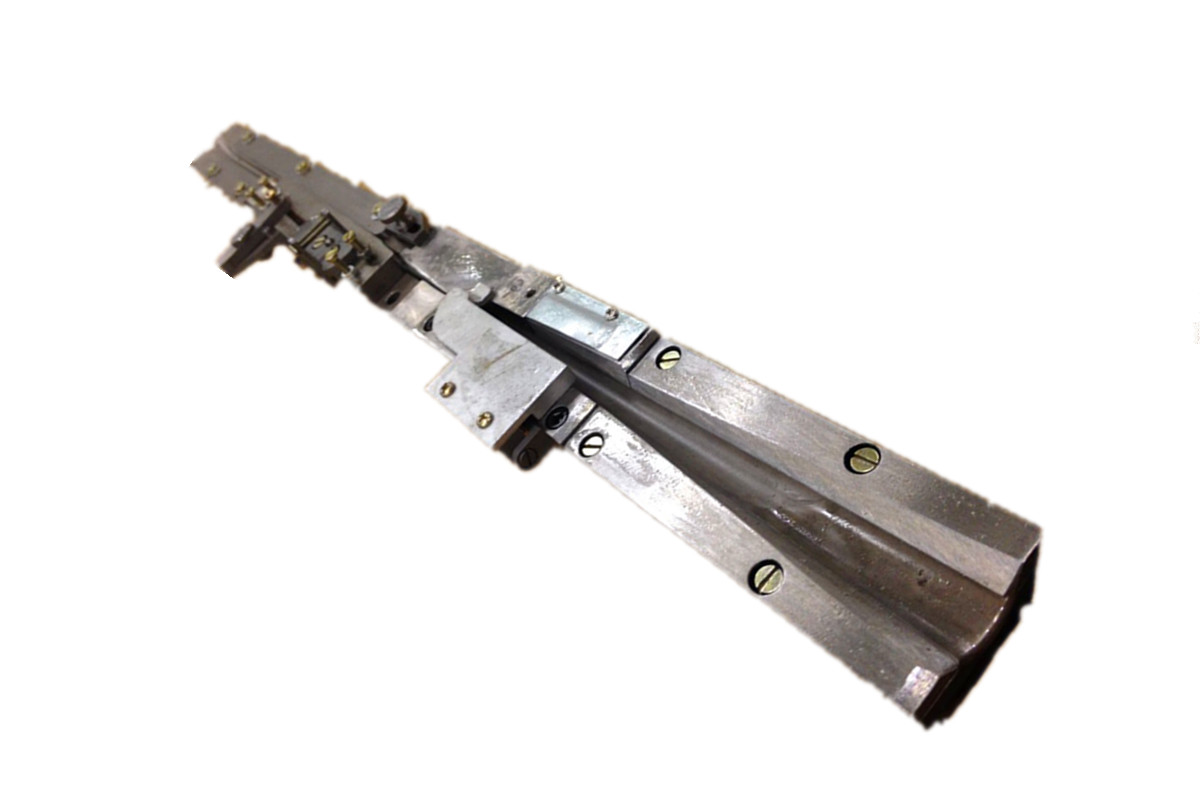

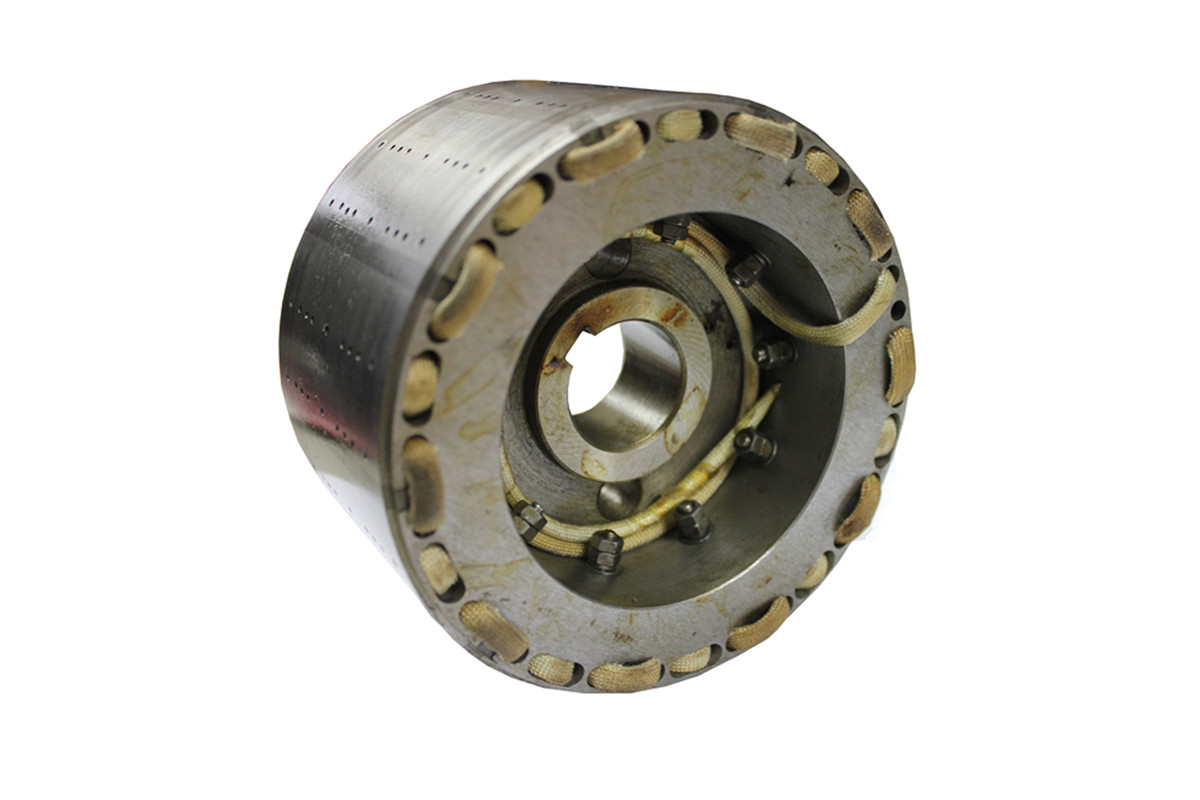

Opener applied with three-level air opening,two-level thread roller opening to completely stretch, loose, spread and gluing uniformity, and the forming machine take high-precision spiral bevel gear and paralleling short shaft driving, single tool rod cutting, to make sure small error of filter rod length.

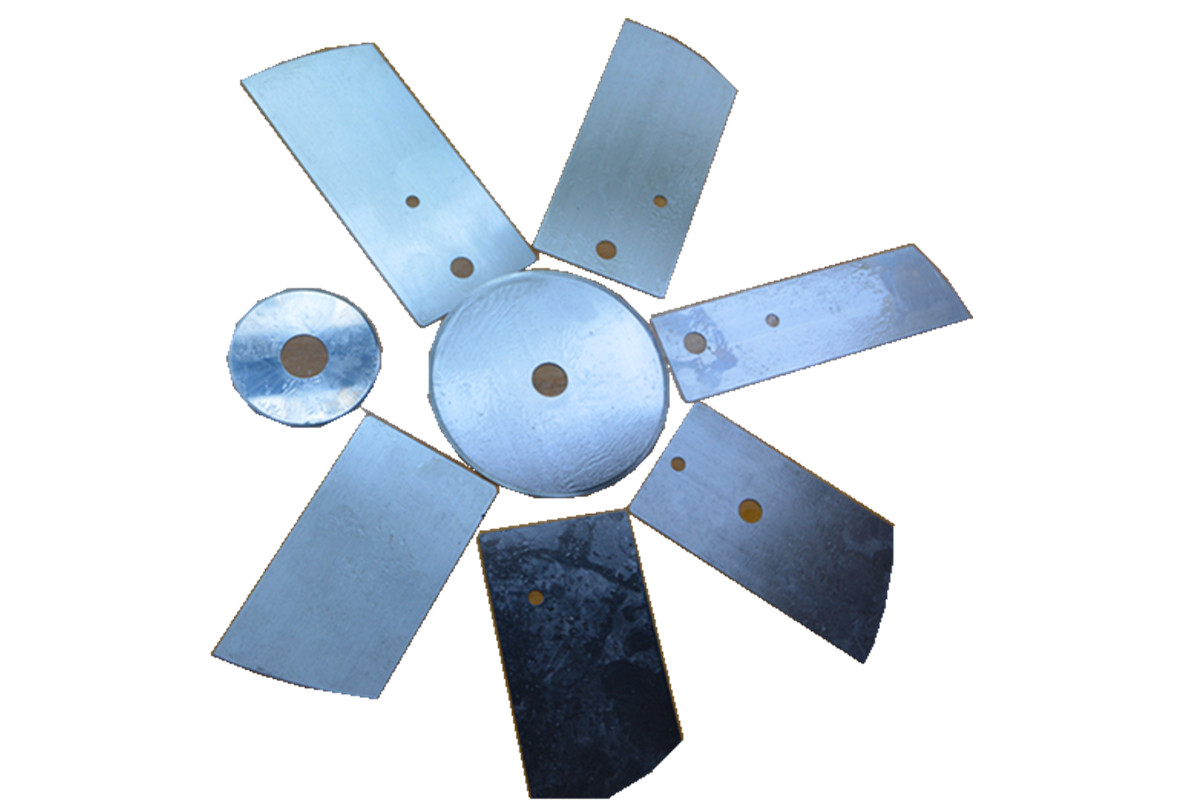

The machine can also use acetate tow and C tow. Opium pipe uses unitary and hot melt adhesive side sealing, making it easy for adjustment and operation, and reliable for splicing. The rod cutting blade applied with automatically cut feeding and automatically sharpen makes the filter rod notch smooth and flattening.

Our ZL23 filter rod maker machine has been widely welcomed by customers from Russia, Ukraine, Poland, Indonesia, Argentina, Brazil, Mexico, etc.

Machine Technical Specifications

| No. |

Parameters |

Propories |

| 1 |

Production Capacity |

250m/min (vinegar fiber) | 160m/min(C fiber) |

| 2 |

Length Of Rod |

120 mm |

| 3 |

Diameter Of Rod |

7.7mm |

| 4 |

Deviation from the circular form |

≤0.35mm |

| 5 |

Power |

380V, 50Hz, 22KW |

| 6 |

Compressed air |

flow≥1.5m3/min, Kpa≥0.5MPa |

| 7 |

Weight |

3500 kgs |